3D Car Modeling in Automobile Industry (Benefits)

Production time and cost are crucial aspects that modern automobile manufacturers worry about. 3D technology has made that easy for them. With 3D car models, automobile engineers can visualize and evaluate several factors of the car during development. Thus, apart from no hefty production costs spent on numerous physical prototype creations, 3D-printed automotive models are also helpful in identifying potential design flaws.

That said, strategic 3D modeling in automotive industry for achieving such designs is significant in this context. The recent breakthroughs in the sector related to 3D modeling enable the industry to save time and cost associated with producing vehicle parts. The various advantages of computer-aided design are thus appreciated and acknowledged by many automobile giants across the globe today. Such as Volkswagen, Toyota, Chevrolet, and the like.

This article will discuss the diverse benefits of 3D car modeling for the automotive industry. We will also talk about the significant role of 3D printing technology and CAD tools in maximizing car manufacturing. Read till the end and learn all the noticeable advantages of 3D designs in the automobile sector.

Reduced costs with 3D automotive design

3D car modeling facilitates automotive prototype creation in a fast and affordable method. 3D modeling and printing are the primary drivers in generating digital design prototypes instead of actual physical models. Thus production costs get reduced to a great extent.

Accelerates design activity

Car 3D modeling has made it possible to create prototypes in hours compared to the months taken earlier. This has been a great boon for designers to unleash maximum speed in the automobile production space. Also, digital modeling makes it easy for designers to work on multiple projects. This not just increases efficiency but also ensures faster production completion.

Improves creativity

Without unique, creative designs, the automobile industry tends to get monotonous. With specialized car modeling software, various unique automobile designs can be developed. These quirky designs inspire car enthusiasts as well as simplify the development process.

Innovations related to automobile design made possible

Not just sparking creativity, 3D automotive modeling is also an innovative method of designing car models. Leveraging rapid prototyping and modeling, designers can go completely paperless. They can also perform unlimited tests virtually before approving a design.

Identifying potential flaws faster

Earlier, unless a machinery part was designed and developed, it was impossible to find any potential design flaws. Today, with 3D modeling and visualization, production designers and engineers can identify design flaws in no time. This is done during the design stage and thus can be rectified immediately.

Reduction of inventory

Innovative vehicle 3D modeling process makes inventory management easier. Usually, high-priced and low-demand automobile parts are stored in far locations. Hence, sourcing them is troublesome. On-demand 3D printing has solved this issue as well. Digital models are printed on-demand, thus reducing storage hassle. As well as less lead time. A fascinating example is Porsche, which produces rare replacement components through 3D printing.

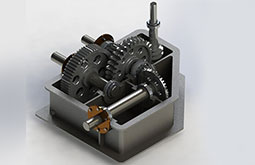

Shorter and simplified assembly process

3D-printed models require fewer materials and fewer components, making procuring and building them much easier. Delphi Technologies, a global automotive aftermarket leader, is the best example.

The automotive spare parts company implemented a metal 3D printing technique, Selective Laser Melting, and designed an aluminum diesel pump. The innovative technique reduced the number of parts required if it was done traditionally. This simplified their production, as well as the assembly process. It also made the final product less prone to damage.

So, you see, the application of 3D technology has brought a paradigm shift in the automobile manufacturing industry. The 3D printed models of bespoke car parts, or the end-use parts for vehicles, tremendously help production costs to remain in check, unlike the earlier traditional methods. Moreover, this additive printing technology can deliver prototypes at a rapid speed, having accurate mathematical representations.

To conclude, 3D vehicle modeling is certain to undergo several more advancements in the future. It’s only a matter of time before we see more innovations in this field. Given the technical nature of these mathematically and geometrically accurate digital versions, it is always best that professionals work on them. Assistance from experts offering best 3D product modeling services is, therefore, the best way of harnessing the technology’s true potential.

So, if you are an automobile manufacturing brand owner or a full-time 3D artist, collaborate with a team of professional 3D experts today.